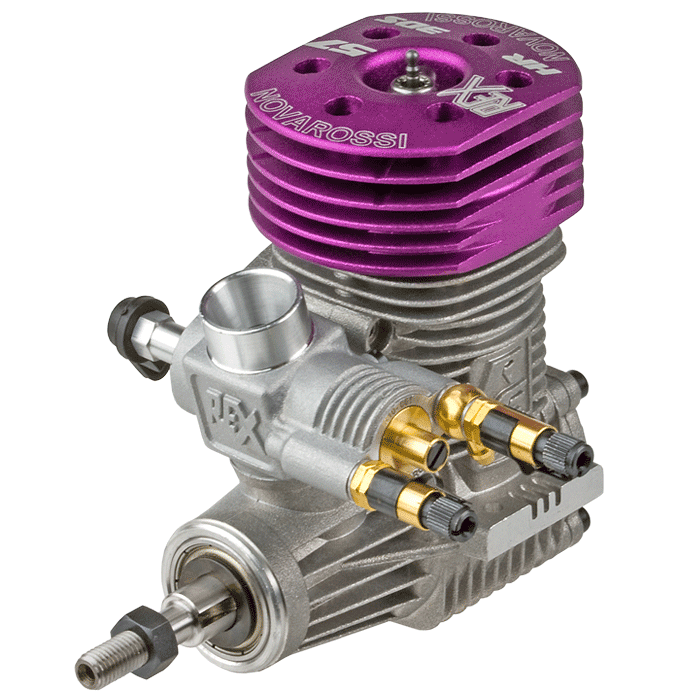

How to Tighten Head Bolts on Novarossi Engines

- Random Q&A

- 17 Dec, 2014

The method head bolts are tightened is very critical for Novarossi model airplane engines. When tightening bolts, a cross pattern method should be used to ensure similar force is being applied to the head as "flatly" as possible. Start first with the bolt at 12 o’clock and then the opposite one at 6 o’clock, the the next bolt at 1 o'clock and then the opposite one at 7 o'clock, and so forth. Starting with very slight pressure and tightening to spec after three or more rounds. You want the head to seat with even pressure on the sleeve. Taking time to do this correctly is very important.

On lapped pistons you can visually check this by the drop in the piston past the exhaust ports. The piston movement should be as free when you finish tightening as it was before you started. This helps insure you have not added any stress to the cylinder during the installation of the head.

Below are some general guidelines to be used for various sized metric bolts on these engines.

2.0 MM - 5-7 in lbs

2.5 MM - 8-10 in lbs

3.0 MM - 13-15 in lbs

4.0 MM - 20-24 in lbs

Glow Plug - 20-24 with gasket

Higher torque values should be used on head bolts with longer thread engagement and the lesser values on back plates, valve covers and carbs, etc.